|

薄壁零件運用數(shù)控技術(shù)的加工

資源天下 2019/6/6 15:15:52

the Processed Thin-walled Part on Computer Numerical Control(CNC) technology

夏啟軍 中國人民解放軍第四八零四工廠職業(yè)技術(shù)學(xué)校 524000

Xia Qi’jun NO.4804 Plant Reputation Technical School of the Chinese People’s Liberation Army

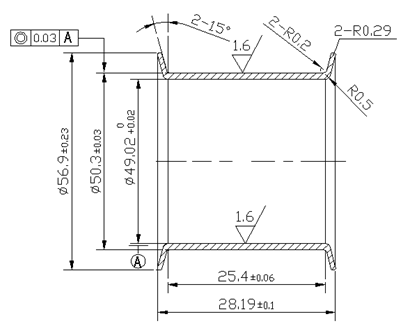

摘要:該論文是本人在數(shù)控車床的實習(xí)教學(xué)中��,學(xué)校在對外加工產(chǎn)品中遇到的一批薄壁零件��。經(jīng)過對圖紙的分析�����,發(fā)現(xiàn)此零件薄壁單邊只有0.64mm����,孔壁非常的薄����,材料為:1Cr18Ni9Ti奧氏體不銹鋼��。而且兩端都有要求極高的圓弧要加工�,多圓弧的相切只能采用數(shù)控車床進行加工�。為了解決裝夾的受力變形和振動的影響,本人設(shè)計并采用了多種材料來做輔助裝夾工具����,通過3次試驗,最后選用尼龍(PA6)作為工裝夾具的材料�。此輔助夾具制造方便,定位精準�,以內(nèi)端面和內(nèi)孔為基準進行定位裝夾。并且制定了一套完整的加工工藝����,加工出了合格的零件。

Abstract: This paper is about the thin-walled component in the external processing commodities when I was in the student teaching of CNC lathe. Through the analysis of the drawing, I found the single side of the component is just 0.64mm. The wall of the hole is very thin. The mater is austenitic stainless steel named 1Cr18Ni9Ti. Both ends required to be processed with high quality. Multi-arc only could be processed by CNC lathe. In order to deal with the problems of transformation of clamping stress and the influence of oscillatory, I designed and used many kinds of materials as assistance clamping tools. Through three times experiments, I chose the Nylon (PA6) as the material of tool clamping. This assistance clamping is very easy to make and it can locate correctly. According to the standard of inner end face and inner hole, it could begin to locate clamping. And I made up a whole series of processed technology to process the qualified components.

關(guān)鍵詞:薄壁零件�;不銹鋼;專用夾具���;端面圓弧

Key words: thin-walled component��;stainless steel�����;specified clamping�;End face arc

前言:薄壁套類零件是應(yīng)用在軸上支承零件及軸上零件的導(dǎo)向等作用,目前已廣泛地應(yīng)用在各個工業(yè)領(lǐng)域����,因為其具有重量輕、節(jié)約材料��、結(jié)構(gòu)緊湊等特點����。隨著一些產(chǎn)品體積小型化,精密化���,薄壁型零件的應(yīng)用也越來越廣泛�����,已經(jīng)成為了許多產(chǎn)品的關(guān)鍵性零件�。但由于薄壁零件壁薄���,剛性差���,加工時容易變形,不易保證加工質(zhì)量��,給零件的機械加工造成困難�。我們可利用數(shù)控車床高加工精度及高生產(chǎn)效率的特點進行加工;數(shù)控車床是按照操作人員編好的零件程序進行自動加工的�����,加工過程中可避免由于操作人員操作失誤造成的人為誤差��。本人充分地考慮到加工工藝問題���,對零件加工質(zhì)量的影響����,為此對刀具材料的選擇和工件的裝夾更加慎重��,對程序的編制等方面進行試驗����,有效地克服薄壁零件加工過程中出現(xiàn)的變形,保證了該零件的加工精度���。

一���、零件圖樣分析

(未完���,下一頁) (未完���,下一頁)

|